Welcome to B/R Instruments

Equipment Building a pilot scale distillation system from steel is an important safety feature

due to the large volume of flammable material being distilled.

Every customer has their own unique needs. Customize the distillation system with the features that are right for you.

High Efficiency

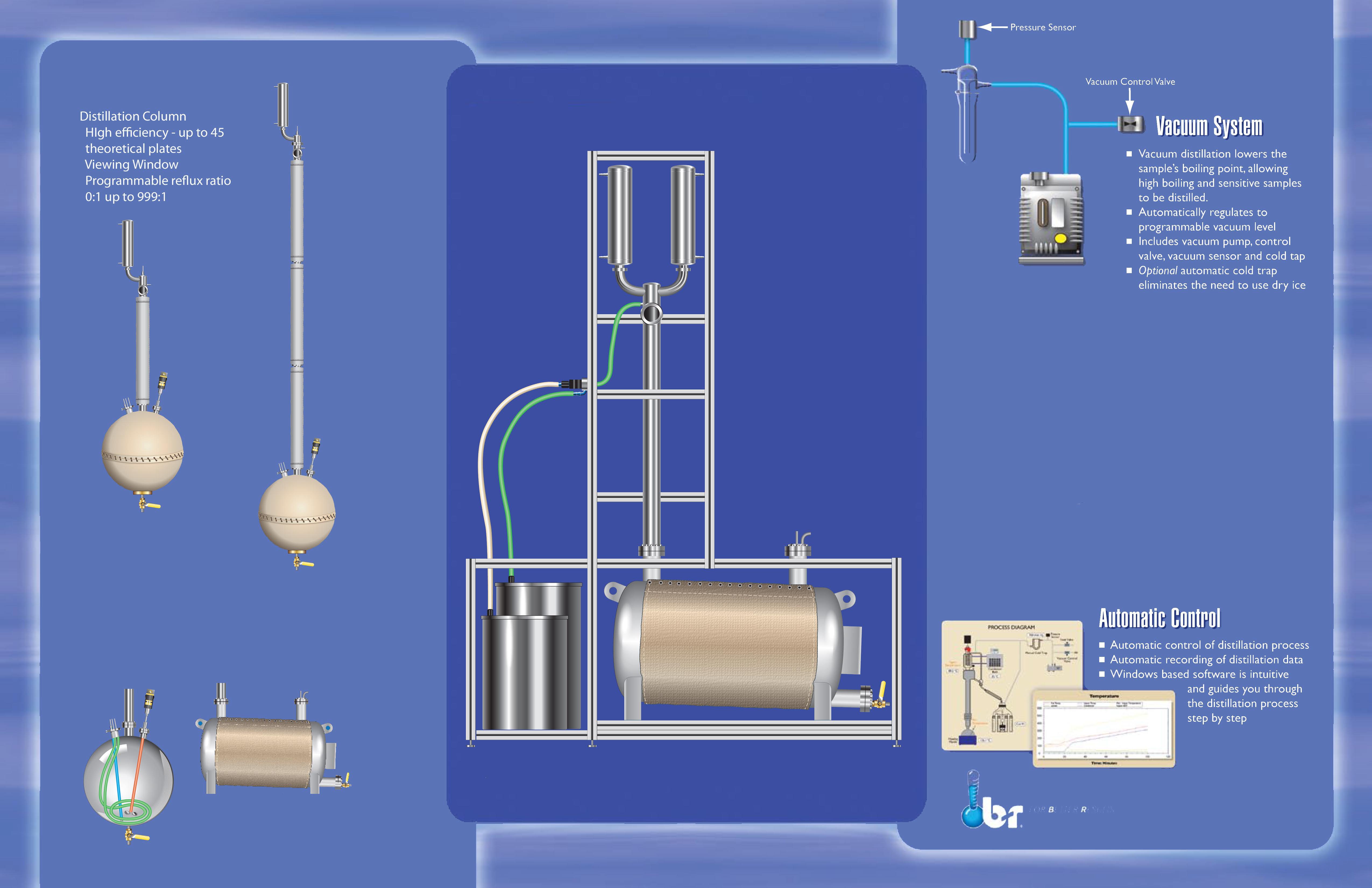

The key to a good fractional distillation system is a high efficiency distillation column. The more efficient the distillation column, the higher the purity of the distilled material.

B/R builds high efficiency distillation columns in 15 theoretical plate sections (approximately 110 cm). Column sections can be stacked 2 or 3 high in order to give 15, 30 or 45 theoretical plates of separating power. You can choose the amount of separating power needed for your application.

Stainless Steel Construction

Building a pilot scale distillation system from steel is an important safety feature due to the large volume of flammable material being distilled. Distillation systems can be made from stainless steel according to your needs. We can also electropolish the distillation system in order to passivate the contact surfaces.

Customized for your Application

The pilot scale fractional distillation system can be configured according to your needs. Automation, vacuum systems, fraction collectors and other accessories can be integrated into the SPC distillation system as needed. The result is a distillation apparatus customized to your specific needs.

Easy to use

The distillation process is fully automated from beginning to end, minimizing the time needed to operate the equipment. Easy programming of parameters makes you feel like a distillation expert. Heating, collecting of distillate and shut down of equipment at completion are all done automatically. Optional control from a PC.

Common applications include:

- Crude Oil Distillation

- Petroleum Distillation

- Biodiesel Distillation

- High Purity Fractional Distillation

- Essential Oil Purification

- Vacuum Distillation

- Research Applications

These high efficiency, pilot scale distillation systems are an ideal tool for batch distillation in the 50 to 1000 liter range.

Every customer has their own unique needs. Customize the distillation system with the features that are right for you.

The most common choice is 304 stainless steel. It provides a good balance between corrosion resistance and price.

- 304 Stainless Steel

- 316 Stainless Steel

The most common choice is the spherical boiler. The most economical is the cylindrical boiler.

Optional View windows allow operator to see inside the boiler. Optional stirring improves heat transfer. Optional quench coils allow quick cooling of the boiler after the distillation is complete.

Options:

- View windows: See inside

- Stirring: Better heat transfer

- Quench Coils: Quick cool down

The most common choice is the 100 mm diameter column. It provides a good balance of throughput and cost.

(2 to 6 inches)

Columns come in 15 plate sections which are approximately 110 cm high.

Most customers choose the 15 plate column which gives good separation and throughput. 30 and 45 theoretical plate columns give better separation but also slower throughput.

Optional Viewing Windows

Choose from standard factory finish for steel surfaces or electro polished surfaces to reduce surface activity.

- Standard Factory Finish

- Electro Polished

Choose a control system. Use B/R's automation or provide your own.

- Automatic

- Automatic with PC Interface

- Manually Operated

Receivers are available in a variety of sizes with optional drain valves and sight glasses

Or provide your own receiver: Many customers already have suitable vessels to collect the distilled material.

Options:

- Drain valves

- Sight glasses

- Viewing Windows

Choose a fraction collector to collect one, two or 4 fractions.

- 1 place

- 2 place

- 4 place

Vacuum reduces boiling points and removes oxygen from the distillation system. Materials that are thermally sensitive or high boiling may need to be distilled under vacuum.

- 100 - 1.0 mmhg

- Other ranges available

- Bio-diesel Distillation

- Crude Oil Distillation

- Essential Oil Distillation

- Solvent Recycling

- Chemical Purification

- Research

- Many More

| Feature | Pilot Scale SPC | Lab Scale Distillation (9600) | Mini Distillation (36-100) | Micro Distillation (800) |

|---|---|---|---|---|

| Distillation Column Diameter | 50-150 mm | 21 mm | 8 mm | 7 mm |

| Distillation Column Length (Standard) | 110 cm | 90 cm | 90 cm | 20 cm |

|

Maximum Theoretical Plates (Spinning Band Type) |

15, 30 or 45 |

Teflon 50 Stainless Steel 15 |

Teflon 200 Stainless Steel 85 |

Teflon 30 Stainless Steel 15 |

| Boiler Sizes | 50 to 1000 liters |

Teflon 50 Stainless Steel 15 |

Teflon 200 Stainless Steel 85 |

Teflon 30 Stainless Steel 15 |

| Boiler Sizes | 50 to 1000 liters | 1 to 50 liters | 100 to 1000 ml | 10 to 100 ml |

| Material of Construction | Stainless Steel | Glass and Teflon | Glass and Teflon | Glass and Teflon |

| Batch Distillation | Yes | Yes | Yes | Yes |

| Automatic Control | Yes | Yes | Yes | Yes |