Welcome to B/R Instruments

Equipment The very efficient distillation column is well suited for producing high

purity materials and making difficult separations.

Specifications for 9600 lab scale fractional distillation by B/R Instrument. Distill samples from 1 to 50 liters

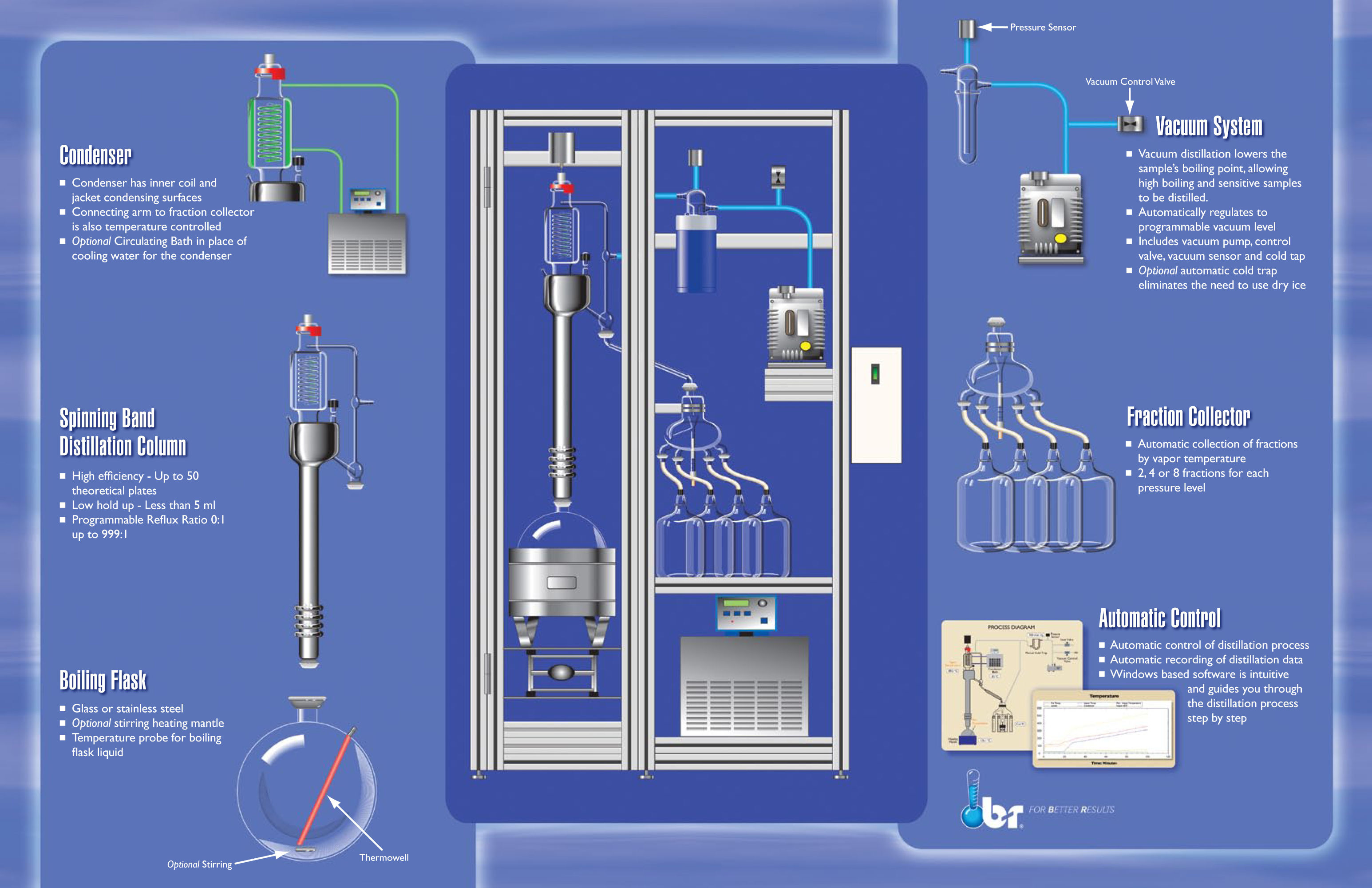

These lab scale fractional distillation systems have up to 50 theoretical plates at atmospheric pressure. The very efficient distillation column is well suited for producing high purity materials and making difficult separations.

Customized for your Application

The 9600 lab scale distillation system can be configured according to your needs. Automation, vacuum systems, fraction collectors and other accessories can be integrated into the distillation system as needed. The result is a distillation apparatus customized to your specific needs.

Easy to Use

The fractional distillation process is fully automated from beginning to end, minimizing the time needed to operate the equipment. Easy programming of parameters makes you feel like a distillation expert. Heating, collecting of distillate and shut down of equipment at completion are all done automatically. Optional control from a PC is available.

Common applications include:

- High Purity Solvent Recycling

- Petroleum Distillation

- Biodiesel Distillation

- Solvent Purification

- High Purity Fractional Distillation

- Essential Oil Purification

- Vacuum Distillation

- Crude Oil Distillation

| Feature | Specifications | Benefit |

|---|---|---|

| Distillation Column Diameter | 21 mm | Large Diameter Provides Maximum Throughput |

| Distillation Column Length | 90 cm Long | Column Provides Maximum Separation |

| Distillation Column Jacket | Vacuum Jacket and Silvered “Mirror” | Prevents Heat Loss from Distillation Column (Adiabatic) |

| Condenser | Inner Coil and Outer Jacket | High Surface Area for Efficient Condensing |

| High Surface Area for Efficient Condensing | Cools Distillate Further Before Going to Receiver | Distillate in Receiver is Close to Room Temperature |

| Boiler Heater | Electrical | Clean, Safe Heating of Boiler |

| Boiler Sizes | 1,2,3,5,12,22 and 50 liter sizes | Available in Glass for Easy Viewing of Sample |

| Boiler Stirring | Standard | Promotes Even Boiling and Gentle Heat Transfer |

| Spinning Band Types | Teflon - Operates up to 225 °C Stainless Steel – Operates Above 225 °C |

High Efficiency and High Temperature Bands |

| Maximum Theoretical Plates | Teflon Band – 50 Stainless Steel - 20 |

High Efficiency Separation Combined with Low “Hold Up” |

| Condensing Bath |

Optional Circulating Bath

|

Automatically Cools and Heats Condenser |

| Fraction Collector |

Standard: 2 Place Optional: 4 Place or 8 Place |

Automatically Collect Fractions According to Vapor Temperature |

| Vacuum Operation |

Optional Vacuum System

|

Automatic Control of Vacuum Level. Vacuum Reduces Boiling Points. Ideal for Thermally Sensitive Samples or High Boiling Materials |

| Automatic Controller | Provides Automatic Control of the Entire Distillation Process | Start the Distillation and Walk Away |

| PC | Optional Control From PC | Perform a Distillation from a PC Analyze Distillation Results using our “Data View” Program. |

| Safety Marks |

|

Safe for Laboratory Use |

| Power (Distillation Unit Only) |

|

Configured for Local Power Requirements and with Local Power Plug, 115 or 220 V, 50/60Hz |

| Other Utilities Required | Cooling Water or Circulating Bath | For Condenser |

| Feature | Pilot Scale SPC | Lab Scale Distillation (9600) | Mini Distillation (36-100) | Micro Distillation (800) |

|---|---|---|---|---|

| Distillation Column Diameter | 50-150 mm | 21 mm | 8 mm | 7 mm |

| Distillation Column Length (Standard) | 110 cm | 90 cm | 90 cm | 20 cm |

|

Maximum Theoretical Plates (Spinning Band Type) |

15, 30 or 45 |

Teflon 50 Stainless Steel 15 |

Teflon 200 Stainless Steel 85 |

Teflon 30 Stainless Steel 15 |

| Boiler Sizes | 50 to 1000 liters |

Teflon 50 Stainless Steel 15 |

Teflon 200 Stainless Steel 85 |

Teflon 30 Stainless Steel 15 |

| Boiler Sizes | 50 to 1000 liters | 1 to 50 liters | 100 to 1000 ml | 10 to 100 ml |

| Material of Construction | Stainless Steel | Glass and Teflon | Glass and Teflon | Glass and Teflon |

| Batch Distillation | Yes | Yes | Yes | Yes |

| Automatic Control | Yes | Yes | Yes | Yes |