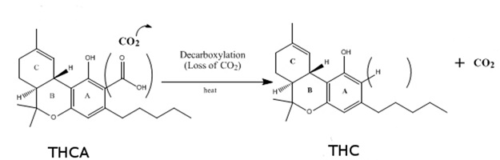

Decarboxylation, also known as decarbing, is the process of converting cannabinoid acids to their corresponding cannabinoids. THCA, CBDA, CBGA, and others undergo a chemical reaction that produce THC, CBD and CBG. Decarboxylation occurs most often due to heat. In the process, a molecule of carbon dioxide is released causing a small loss of weight. These cannabinoid acids are not considered psychoactive and decarboxylation allows for their use in edibles and other common products.

In the process of cannabis or hemp distillation, decarbing after extraction has several benefits. By using heat and relatively light vacuum, volatile removal can occur at the same time. These volatiles can easily foul vacuum pump oil and prevent a deep vacuum during distillation. The production of CO2 can also disrupt the pressure in a distillation system. The combined act of decarbing and devolatilizing ahead of time can speed up the production of your finished distillate.

The B/R stainless steel Decarber is a jacketed reactor ideal for decarbing cannabis oil.

Decarb Reactor Features

- Rugged stainless steel extractor construction. No glass to break!

- Temperature control of jacket with digital bath.

- Viewing windows makes it easy to see the reactor contents

- Drain valve to remove decarbed oil

- Temperature measuring port to monitor the temperature of reactor contents

- Insulated body and bottom.

- Electro polished surfaces

- Sanitary connections

- Clean in place (CIP)

- Easy to dissemble

- Welded stainless steel mounting frame with wheels

- IQ/OQ/PQ documents

Safety Features

- Compressed air powered stirrer

- Heating/cooling bath can be located outside the room or operation

- High surface area condenser to handle solvents.

- Fill reactor with cannabis oil

- Turn on stirrer and heat contents with bath connected to reactor jacket

- Maintain reactor at about 85 C for 45 minutes

- Cool reactor to 60 C and empty.

Your Decarbed oil is now suitable for Wiped Film, Short Path or B/R Spinning Band distillation