Some extraction techniques bring a lot of water-soluble contaminants into the crude extract. Among the contaminants are sugars, phospholipids, and pigments. Liquid-liquid extraction using water on the crude extract can remove these contaminants from oil into the water. Water extracted oil has better visual appeal, higher purity, and improved post-extraction processing of cannabinoids.

These water-soluble compounds can cause charring and fouling in the distillation apparatus. Continuously operated equipment must be broken down to handle the buildup of these residues. Many of these more polar compounds cannot be separated by distillation either.

Extractor Features

GMP Features

Safety Features

Procedure

- Rugged stainless steel extractor construction. No glass to break!

- Temperature control of jacket with digital bath

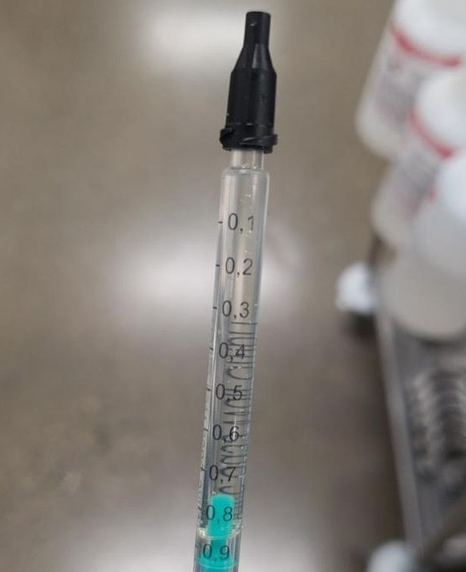

- Temperature measuring port to monitor the temperature of extractor contents

- Viewing windows makes it easy to see the reactor contents

- Drain valve to remove water-soluble contaminants

GMP Features

- Electro polished surfaces

- Sanitary connections

- Clean in place (CIP)

- Easy to dissemble

- Welded stainless steel mounting frame with wheels

- IQ/OQ/PQ documents

Safety Features

- Compressed air powered stirrer

- Heating/cooling bath can be located outside the room or operation

Procedure

- Add cannabis oil to the extractor

- Turn on extraction water and stirring

- Maintain the water/oil interface near the middle of the reactor

- Remove when extraction is complete

Your water extracted oil is now suitable for Wiped Film, Short Path or B/R Spinning Band distillation