Welcome to B/R Instruments

Vacuum Distillation

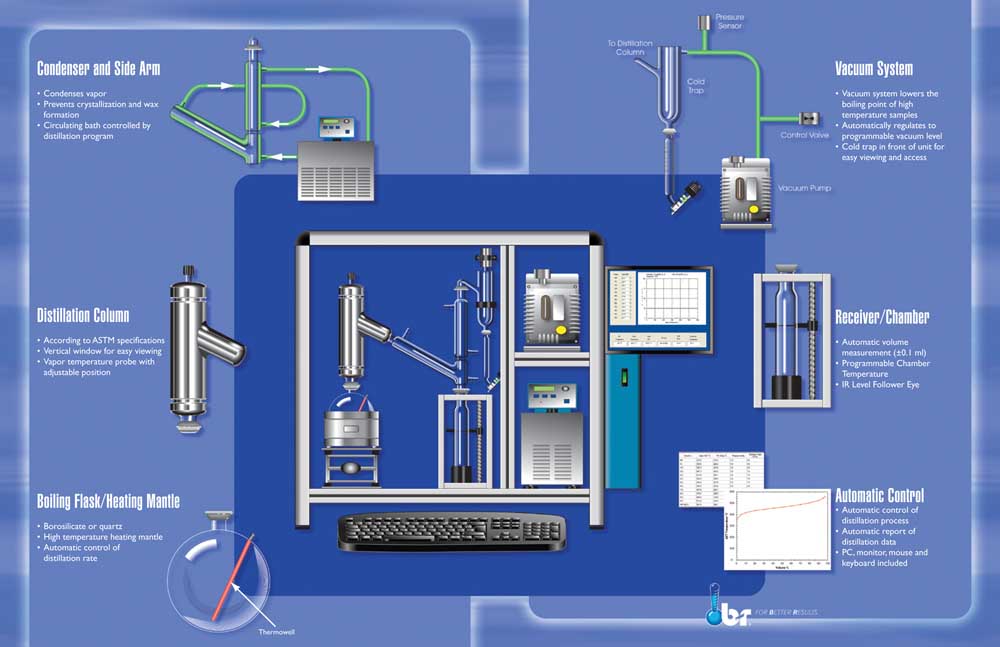

This system performs the D1160 vacuum distillation automatically. Just put sample in the boiling flask and start the test. Everything else is done automatically including:

- Vacuum Control

- Distillation rate control

- Condenser and receiver temperature

- Recording of distillation data, first drop (IBP) and final boiling point (FBP)

- Detection of cracking and boiling flask over-temperature

- Ending of distillation, cool down and generation of the final report

PC control automates the D1160 test from beginning to end. New and experienced operators will find this system simple to use. The software steps you through the testing process from start up to printing of results.

Easy to understand software and easy access to all the distillation components makes performing the test as simple as possible

- Distillation rate

- Vacuum level

- Degassing

- Receiver/condenser temperatures

- Printing of results

Results Automatic Detection and Recording of

- First drop detection (IBP)

- Distillation rate

- Vapor and liquid temperatures, vacuum level

- Receiver volume

- Final boiling point (FBP)

- Calculation of vapor AET

- Sample cracking

Boiling Flask/Heating Mantle

- 500 ml

- Borosilicate or quartz

- High wattage heating mantle

- Insulating top

- Automatic cool down fan

Distillation Column

- According ASTM specifications

- Vertical viewing window for easy viewing

- Highly reflective vacuum jacket

- Adjustable vapor temperature probe

First Drop Detector

- Automatically detects and records the first drop (IBP)

Receiver/Volume Measurement

- Precision diameter (±0.01 mm)

- Automatic precision volume measurement (±0.1 ml)

- Programmable chamber temperature

- IR level follower eye

- Automatic control)

- Programmable

- 30-100°C Standard

- Optional -10 to 100 °C

- Low liquid cut off

- Over temperature cut off

Vacuum Operation

- Automatic control

- Programmable

- Automatic degassing

Vacuum Components

- 100-1 mmHg range standard (MKS)

- Optional 760-100 mmHg range (MKS)

- Optional 1-0.1 mmHg range (MKS)

- Automatic control valve (MKS)

- Vacuum pump (Edwards)

Cold Trap

- Cooling by dry ice

- Optional automatic cooler, -60 °C

- Graduated

- Easy access

- Easy to see contents

- Easy to remove contents

Optional Foam Sensor

- Automatically detects foam formation

PC/Monitor

- Included with distillation unit

- Keyboard and monitor integrated into distillation system

Dimensions

- 91.5 cm x 94 cm x 53 cm (H x W x D)

Power (Distillation Unit Only)

- 10 amps 220 VAC

| Fully Automatic | Semi-Automatic | Manually Operated | |

|---|---|---|---|

| Digital Temperature and Vacuum Display | |||

| Vacuum Control | |||

| Distillation Rate | |||

| Volume Measurement | |||

| Condenser/Receiver Temperature | |||

| Shut Down on Test Completion | |||

| Control and Test Report from PC |

There are so many reasons to choose a B/R Fully Automatic Crude Oil Distillation System. Here are a few.

Sometimes the sytsem with the smallest footprint can be the most difficult to operate because there just isn't enough room to operate it. The B/R system has a small footprint but still allows enough room for the operator to perform routine tasks.

the "open" design makes maintenance simple. Pump oil level and bath level are in the front of the unit and at eye level. It couldn't be any easier.

Ours is in the front of the unit (easy access) and is made of glass so you can see if anything is trapped inside (easy to use). And you can warm up our cold trap between samples as required by ASTM D1160!

Brand name components

This system features well known brand components such as Edwards vacuum pump, MKS vacuum system and Polyscience bath. Strickly, top of the line stuff.